Showing 208–216 of 297 results

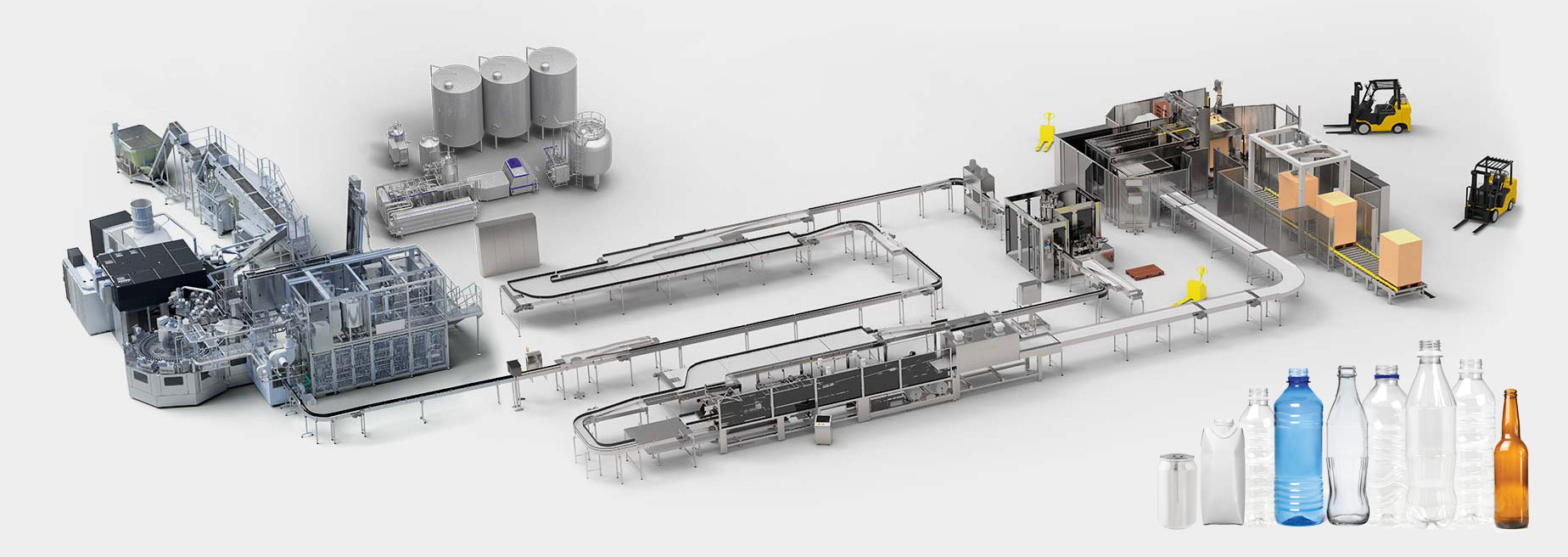

Versatile Filling Machine Solutions for All Industries

At Jiangsu Mic Machinery, we specialize in developing and manufacturing world-class filling machine solutions tailored to the evolving needs of modern packaging industries. From beverages to edible oils and carbonated drinks, our equipment ensures efficiency, hygiene, and high precision for various liquid products.

⚙️ What Is a Filling Machine?

A filling machine is a vital part of liquid packaging lines, responsible for transferring products into containers with speed, consistency, and minimal waste. Depending on the industry and product type, the machine may vary in structure and operation.

We offer specialized solutions including:

• Beer filling machine for breweries

• Beverage filling machine for juice, tea, or dairy drinks

• Carbonated drink filling machine for fizzy beverages

• Oil filling machine for edible and industrial oils

• Juice filling machine for pulpy or clear juices

• Soda filling machine and soft drink filling machine for flavored carbonated drinks

• Water filling machine for mineral and purified water bottling

🧃 Complete Beverage Filling Solutions

|

Our advanced beverage filling machine systems are used across juice plants, soft drink factories, and bottled water production lines. Whether you need a juice filling machine with hot-fill capabilities or a soft drink filling machine with CO₂ retention, we have the right equipment for your needs. For carbonated drinks, our carbonated drink filling machine is engineered to prevent foaming and gas loss, with a robust design that handles both PET and glass bottles efficiently. |

🍺 Brewery-Grade Beer Filling Machines

|

We manufacture durable and efficient beer filling machine systems designed for microbreweries and large beer bottling plants. These machines offer accurate volumetric control, clean-in-place (CIP) functionality, and seamless integration with capping units. Whether you're bottling in glass or can, our systems maintain product quality from the first fill to the last. |

|

📐 Filling Machine Technical Specifications

Carbonated Bottle Filling Machine:

|

Model |

MIC12-12-1 |

MIC18-18-1 |

MIC18-18-6 |

MIC24-24-6 |

MIC24-24-8 |

MIC32-32-8 |

MIC Semi Automatic |

|

Application |

Beer, Carbonated Beverage, Gas Drinks, Sparking Water And So On |

||||||

|

Packing Type |

Aluminum Bottle, Metal Bottle, Tin Bottle, PET Bottle, etc |

||||||

|

Speed |

600-1000BPH |

1000-1500BPH |

2000-4000BPH |

4000BPH |

2000-6000BPH |

4800-7500BPH |

200-800BPH |

|

Filling Arrange |

180ml, 250ml, 330ml, 355ml, 440ml, 500ml, 8oz, 12oz, 16oz, 1L and so on (0.1-1L) |

||||||

|

Power |

2.2KW |

1.5KW |

1.5KW |

5.0KW |

0.3KW |

||

|

Size |

2.5*1.9*2.3 (M) |

2.2*1.8*2.55 (M) |

2.5*1.4*2.5 (M) |

3.4*2.5*2.3 (M) |

2.0*0.7*2.0 (M) |

||

|

Weight |

3500KG |

3500KG |

4500KG |

10000KG |

150KG |

||

Non-carbonated Bottle Filling Machine:

|

Model |

MIC 12-1 |

MIC 8-8-3 |

MIC 14-12-5 |

MIC 18-18-6 |

MIC 18-18-6 |

MIC 24-18-6 |

MIC Linear |

|

Application |

Juice, Cold Coffee, Herbal Tea, Non-carbonated Drinks And So On |

||||||

|

Packing Type |

Aluminum Bottle, Metal Bottle, Tin Bottle, PET Bottle, etc |

||||||

|

Speed |

500-2000BPH |

2000-2500BPH |

3000-5000BPH |

8000-15000BPH |

8000-10000BPH |

10000-13000BPH |

1800BPH |

|

Filling Arrange |

180ml, 250ml, 330ml, 355ml, 440ml, 500ml, 8oz, 12oz, 16oz, 1L and so on (0.1-1L) |

||||||

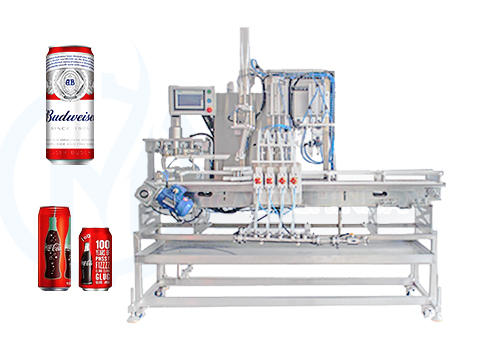

Carbonated Can Filling Machine:

|

Model |

MIC 12-1 |

MIC 18-1 |

MIC 18-6 |

MIC 24-6 |

MIC 32-8 |

MIC 40-10 |

MIC 4-4-1 |

MIC Semi Automatic |

|

Application |

Beer, Carbonated Beverage, Gas Drinks, Sparking Water And So On |

|||||||

|

Packing Type |

Aluminum Cans, Metal Cans, Tin Cans, PET Cans, etc |

|||||||

|

Speed |

1000-2000CPH |

1000-2500CPH |

3000-6000CPH |

4000-8000CPH |

6000-10000CPH |

8000-15000CPH |

1000-1500CPH |

|

|

Filling Arrange |

180ml, 250ml, 330ml, 355ml, 440ml, 500ml, 8oz, 12oz, 16oz, 1L and so on (0.1-1L) |

|||||||

|

Power |

1.1KW |

1.5KW |

2.5KW |

3.5KW |

4.2KW |

5.5KW |

2.0-3.5KW |

|

|

Size |

1.8*1.3*1.95 (M) |

1.9*1.3*1.95 (M) |

2.3*1.4*1.9 (M) |

2.58*1.7*1.8 (M) |

2.8*1.7*1.95 (M) |

3.0*1.9*2.1 (M) |

2.2*1.15*2.05 (M) |

5.75*5.5*4.8 (M) |

|

Weight |

1800KG |

2100KG |

2500KG |

3000KG |

3800KG |

4500KG |

550KG |

15KG |

Non-carbonated Can Filling Machine:

|

Model |

MIC 12-1 |

MIC 18-6 |

MIC 24-6 |

MIC 32-8 |

MIC 40-10 |

|

Application |

Juice, Cold Coffee, Herbal Tea, Non-carbonated Drinks And So On |

||||

|

Packing Type |

Aluminum Cans, Tin Cans, PET Cans, etc |

||||

|

Speed |

1000-2000CPH |

4000-7000CPH |

4000-8000CPH |

10000CPH |

12000CPH |

|

Filling Arrange |

130ml,250ml, 330ml, 355ml, 500ml, 120z, 16oz, 1L and so on (0.1-1L) |

||||

|

Powder |

1.1KW |

2.5KW |

3.5KW |

4.2KW |

5.5KW |

|

Size |

1.8*1.3*1.95 (M) |

2.3*1.4*1.9 (M) |

2.58*1.7*1.8 (M) |

2.8*1.7*1.95 (M) |

3.0*1.9*2.1 (M) |

|

Weight |

1800KG |

2500KG |

3000KG |

3800KG |

4500KG |

🛢️ Reliable Oil Filling Machines

|

The oil filling machine series is ideal for edible oils like olive oil, sunflower oil, and cooking oil, as well as industrial-grade oils. We offer both gravity-based and piston filling models to handle varying product viscosities. Our machines ensure drip-free performance and accurate filling for all packaging volumes. |

💧 Water and Soda Bottling Experts

|

Our high-speed water filling machine and soda filling machine lines are among the most trusted in the industry. Whether you need a compact machine for startups or a large-capacity system for commercial use, Jiangsu Mic Machinery delivers optimized results. For those in the carbonated beverage sector, the soft drink filling machine offers customizable filling heads, CO₂ injection, and temperature control to preserve taste and shelf life. |

|

🥫 Advanced Can and Bottle Filling Capabilities

Whether your product is packed in cans, glass, or plastic, our machinery can adapt. The can filling machine is built with durable components to ensure smooth operations with aluminum or tin cans. Likewise, our glass bottle filling machine and PET bottle filling machine lines handle everything from still water to flavored sodas.

Each model includes options for filling, capping, labeling, and packaging—offering a turnkey solution for manufacturers worldwide.

✅ Why Choose Jiangsu Mic Machinery?

With decades of manufacturing excellence, Jiangsu Mic Machinery is trusted by global clients across the beverage, food, chemical, and pharmaceutical sectors. Our filling machines stand out for their:

• High-speed automation

• Hygienic stainless steel construction

• Industry-specific configurations

• Long-term operational stability

• Competitive pricing and global service support

We offer complete project consultation—from design and engineering to installation and after-sales service.

📞 Get Your Customized Filling Solution Today

If you're looking for a reliable beer filling machine, beverage filling machine, or a high-performance PET bottle filling machine, contact Jiangsu Mic Machinery today. We’ll help you find the right equipment to streamline your production and grow your business.

📧 Email: lewis@micmachinery.com

🌐 Website: www.micbeveragemachine.com

📞 WhatsApp/Phone: 0086-13961211672