Showing 10–18 of 17 results

Packing Machine Solutions by Mic Machinery

⚙ Reliable Packing Automation for Modern Industries

At Mic Machinery, we understand the crucial role of efficient packaging in modern manufacturing. Whether in food, beverage, pharmaceutical, chemical, or consumer goods industries, the final step of product handling—packing—determines how goods reach customers safely and professionally. Our packing machines are engineered to ensure seamless operations, reduced labor intensity, and enhanced throughput across production environments. By automating the transition from product to pallet, Mic Machinery’s systems help manufacturers lower operational costs while boosting packaging speed and consistency.

As production scales up and market competition intensifies, packaging becomes more than just a protective shell—it’s an integrated part of supply chain performance, brand perception, and regulatory compliance. Mic Machinery offers intelligent packing solutions designed to keep your packaging line in sync with upstream filling, labeling, and coding operations. Our machines are built for performance, engineered for precision, and customized for industry-specific demands.

⚙ Why Efficient Packing Machines Matter

|

In today’s automated manufacturing ecosystem, packing machines are no longer optional—they are foundational. Without the right packing solution, even the most advanced filling or labeling systems may fall short of their full potential. Packing equipment provides the critical bridge between production and logistics, managing everything from primary and secondary packing to final palletization. Poorly executed packing processes can lead to damaged goods, slow dispatch times, and dissatisfied clients.

Moreover, modern buyers and supply chain partners demand faster delivery, cleaner packaging, and traceability—necessitating precision at every step of the packaging process. Whether handling fragile glass bottles, flexible pouches, bulk cartons, or mixed-sized items, Mic Machinery’s packing equipment offers adaptability and reliability. We ensure that no matter the product type or industry, your packaging output remains consistent and scalable. |

|

A well-integrated packing system minimizes downtime, reduces manual labor, and increases production safety by limiting human handling of heavy or repetitive tasks. These efficiencies become especially vital in regulated industries like pharmaceuticals or food and beverage, where hygiene, traceability, and consistency are key.

⚙ Comprehensive Range of Packing Machines

Mic Machinery provides a well-rounded selection of packing machines to meet different production line requirements, each designed to fit seamlessly within high-speed, automated environments:

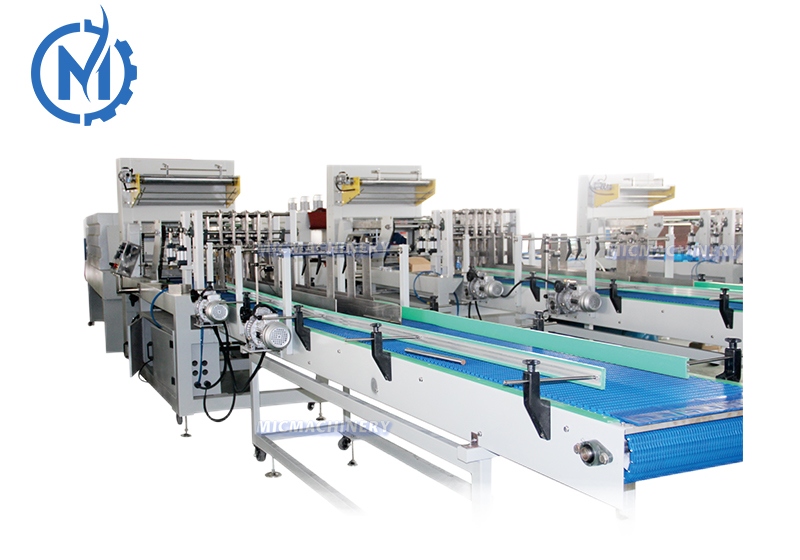

☞ Wrap Packing Machine: Designed for packaging individual or grouped products using stretch or shrink film. Ideal for beverages, cosmetics, and pharmaceuticals that require a tamper-proof seal or transport stability.

☞ Carton Packing Machine: Automates the process of forming, filling, and sealing corrugated cartons. Commonly used for boxed food, electronic components, or bundled consumer goods.

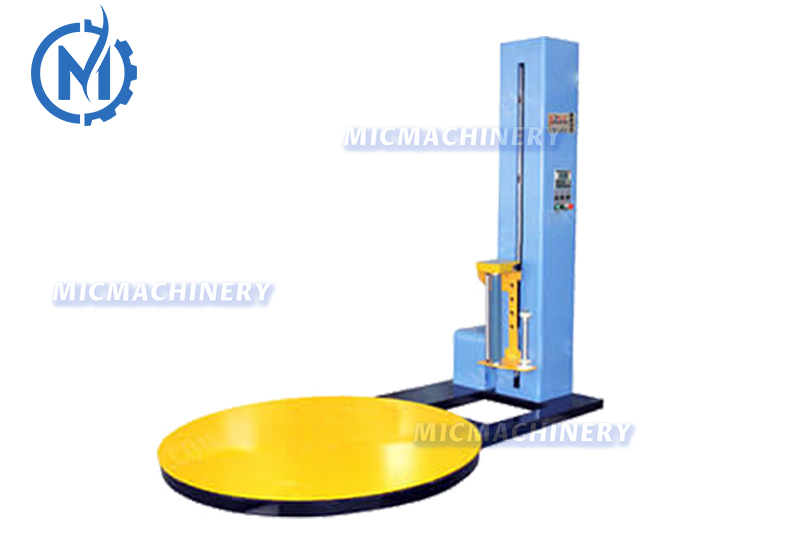

☞ Pallet Wrapping Machine: Stabilizes products on pallets using stretch film, ensuring secure transport and optimized space utilization in logistics.

☞ Depalletizer: Automatically removes products from pallets to feed upstream machines, useful in bottle or can lines where raw containers are delivered in bulk.

☞ Palletizer: Automates the loading of cartons or wrapped products onto pallets in predefined patterns, boosting efficiency and reducing manual lifting.

All Mic Machinery packing solutions are compatible with our labeling and coding systems, ensuring end-to-end traceability and consistent presentation.

⚙ Technical Specifications

Wrap Packing Machine:

|

Model |

MIC-20P |

MIC-10B |

MIC-15B |

MIC-20B |

|

Dimension for the whole unit |

11840*1100*2100mm |

6500*3200*2100mm |

11083*1100*2100mm |

11840*1100*2100mm |

|

Thermal shrinkage passage dimension |

2400*650*450mm |

1800*650*400mm |

2400*650*450mm |

2400*650*450mm |

|

Max package dimension |

600*400*350mm |

600*400*350mm |

600*400*350mm |

600*400*350mm |

|

Packaging speed |

15Pcs/minute |

8-10Pcs/minute |

10-15Pcs/minute |

15Pcs/minute |

|

Transfer belt width |

550mm |

304mm |

550mm |

550mm |

|

Sealing and cutting time/temperature |

0.5-1.5s 180°C-260°C |

0.5-1.5s 140°C-160°C |

0.5-1.5s 180°C-260°C |

0.5-1.5s 180°C-260°C |

|

Operating power supply/power |

380V 30kw |

380V 24kw |

380V 30kw |

380V 30kw |

|

Operating air pressure |

0.6-0.8Mpa |

0.6-0.8Mpa |

0.6-0.8Mpa |

0.6-0.8Mpa |

|

Air Consumption |

0.6m³/minute |

/ |

0.6m³/minute |

0.6m³/minute |

Carton Packing Machine:

|

Model |

MIC-10C |

MIC-15C |

MIC-35C |

|

Carton size |

L260-535* W260-420*H130-330 |

L260-535* W260-420*H130-330 |

/ |

|

Speed |

10 carton/min(according to the carton size) |

17 carton/min(according to the carton size) |

10-14case/ minute |

|

Dimension |

1950*1500*1450mm |

1950*1500*1450mm |

6285*2582*2115 |

|

Power supply |

220V;50Hz |

220V;50Hz |

380V,three-phase |

|

Table high |

Min 600mm; Max 720mm |

Min 600mm; Max 720mm |

/ |

|

Tape width |

45~72mm |

45~72mm |

/ |

|

weight |

300kg |

400kg |

3.5T |

Pallet Wrapping Machine:

| Model | Pallet Wrapping Machine | Wrapping Machine for Pallets | Industrial Pallet Wrapping Machine |

| Wrapping size | 1200*1200*1800mm | 1200*1200*2100mm |

500-1300*500-1300 |

| Conveying height | 500mm | 500mm | |

| Rocker speed | 18 rpm | 0-15 rpm | 0-12 rpm |

| Power supply voltage | 380V/50HZ | 220V/50hz | 220V/50Hz |

| Machine power | 2.2KW | / | 1 KW |

Palletizer:

|

Model |

Robotic Palletizing System | Palletizing Machine | Automatic Palletizing System |

|

Standard capacity |

7 cartons /min | 15 packs/min (max) Note: The palletizing speed is related to the size of the pallet and the grouping form of each layer. | 24 bottles (500ml) max 33 packages/min, 12 bottles (1000ml) max 33 packages/min, 6 bottles (1500ml) max 33 packages/min |

|

Motor power supply/power |

200-600V,50-60Hz |

AC 380V/50HZ, 8 KW |

AC 380V/50HZ, 10KW |

|

Equipment size |

1140*1140*140mm | 2500 * 2500 *3500mm | 10000 *6500 × 400mm |

|

Environmental conditions |

0℃- 45℃ |

temperature 0-45 ℃ humidity 40-95% |

Temperature: 0-40°C, Humidity: 40-95% |

|

Equipment weight |

925kg |

1500KG |

7500KG |

⚙ Engineered for Flexibility and Integration

|

Mic Machinery's packing equipment is designed with real-world factory challenges in mind. One of the most valuable aspects of our systems is their flexibility—they adapt to varying product sizes, material types, and packaging patterns without requiring excessive downtime or format changes. Our wrap and carton packers can handle multiple SKUs, ideal for contract packaging operations or facilities producing seasonal product variants.

In addition, our machines integrate easily with upstream and downstream systems, including bottle filling machines, sleeve labeling systems, vision inspection units, and robotic arms. This modular approach enables phased upgrades and customized configurations, allowing our clients to scale their automation journey based on operational growth or budget availability. |

We also prioritize human-machine interaction (HMI). Our packing machines feature user-friendly interfaces with real-time error diagnostics, memory for multiple packaging formats, and remote service capabilities. This significantly reduces operator training time and improves day-to-day usability, especially in facilities with high employee turnover.

⚙ Running video of Packing Machine

⚙ A Partner in Long-Term Packaging Efficiency

Choosing a packing machine from Mic Machinery is more than selecting a piece of equipment—it’s entering a partnership focused on long-term operational excellence. Our engineering team collaborates closely with each client to design packing lines that support your specific production goals, whether it's reducing packaging waste, increasing speed, or improving pallet stability for export logistics.

Every Mic Machinery packing solution is backed by strong after-sales support, including global commissioning, remote troubleshooting, and access to wear parts. We understand that downtime costs more than repairs—so we emphasize reliability and maintainability from design to deployment.

Whether you're a start-up setting up your first automated line or a multinational upgrading to Industry 4.0 standards, Mic Machinery’s packing systems help you package products faster, safer, and more intelligently. With robust structure, intelligent control, and integrated automation, our packing machines prepare your products not just for shipping, but for marketplace success.