Showing 1–9 of 43 results

Reliable Auxiliary Machines for Efficient Production

⚙ About Mic Machinery

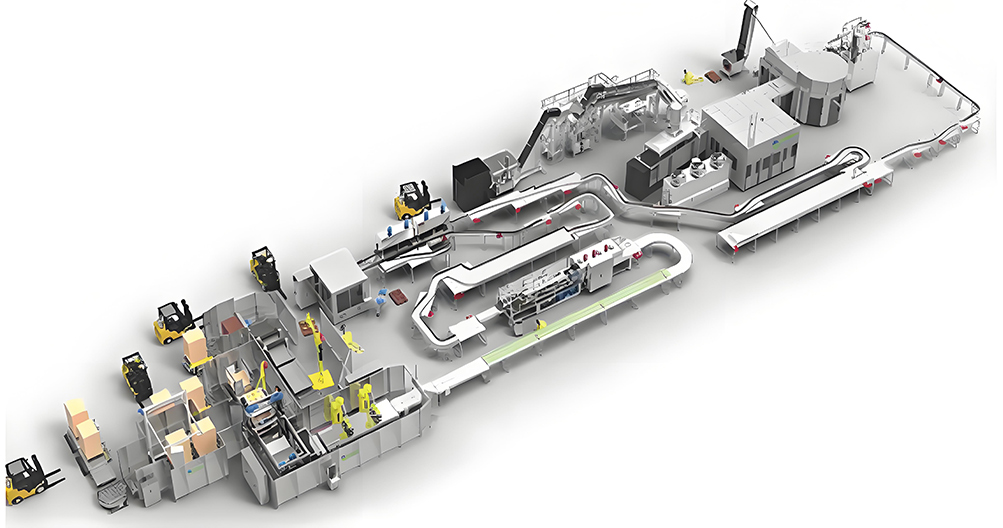

Mic Machinery is a leading manufacturer specializing in advanced filling and packaging machinery for both the food and pharmaceutical industries. With decades of engineering expertise and a strong commitment to innovation, our company has built a solid reputation for delivering high-performance, customized solutions to global clients. From automated bottling systems to cutting-edge labeling equipment, Mic Machinery is at the forefront of production technology—ensuring safety, precision, and efficiency across every project we undertake. As part of our continuous growth and product diversification, our Auxiliary Machine category plays a vital role in supporting primary manufacturing systems with added functionality, improved workflow, and greater productivity.

We work closely with clients to understand their operational needs and compliance challenges. Our engineering team designs every auxiliary solution to align with specific production goals—whether improving hygiene, reducing downtime, or increasing packaging efficiency. With strong technical capabilities and dependable service, Mic Machinery continues to grow as a trusted partner in the manufacturing world.

⚙ What Is an Auxiliary Machine?

Auxiliary machines are supportive production devices that enhance, complement, or streamline core manufacturing processes. While not always part of the main production line, these machines are essential for optimizing performance, maintaining hygiene, ensuring compliance, and extending the lifespan of the primary equipment.

In both food processing and pharmaceutical manufacturing, auxiliary equipment helps maintain operational consistency, safety, and cost-effectiveness. For example, sterilization systems ensure microbial safety, while detection units safeguard against defects. These machines handle tasks that, while often behind the scenes, are indispensable for ensuring that products meet regulatory and consumer standards.

At Mic Machinery, we recognize that seamless integration is key. That’s why our auxiliary machines are built for compatibility, efficiency, and reliability—allowing manufacturers to elevate their production line without sacrificing simplicity or control.

⚙ Main Auxiliary Products

|

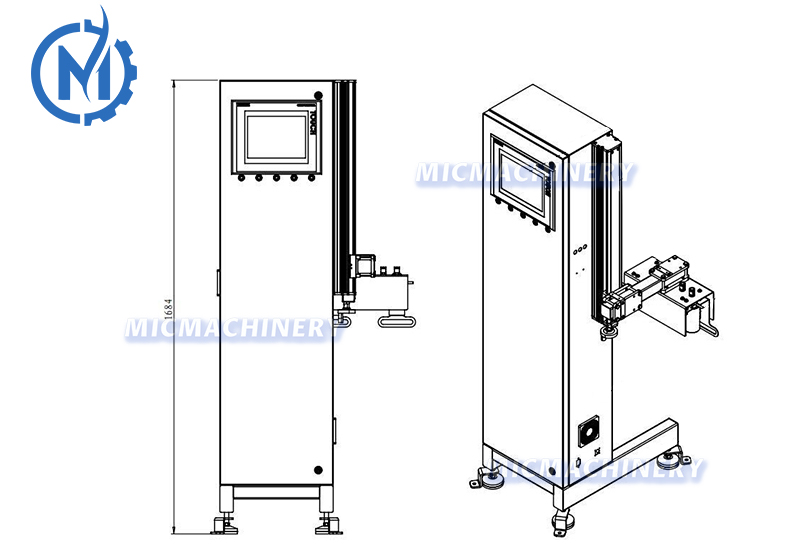

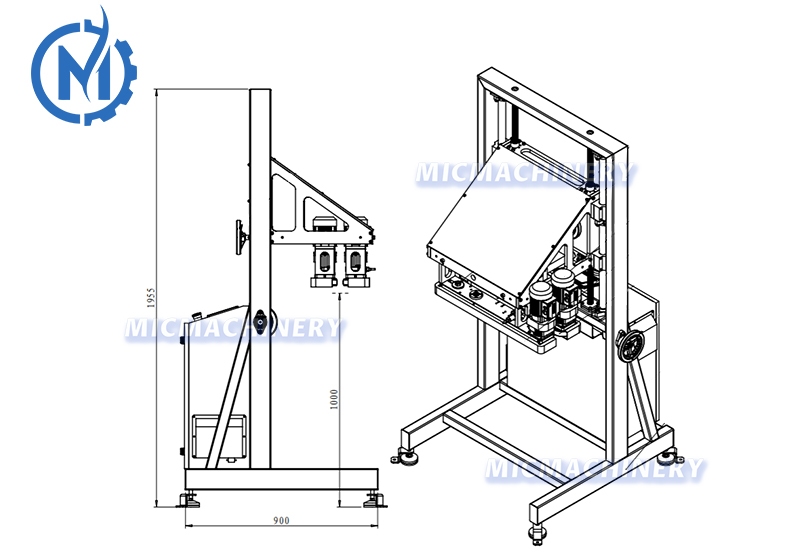

At present, Mic Machinery’s Auxiliary Machine lineup includes several core product types: beverage processing systems, sterilization units, liquid nitrogen dosing systems, and detection equipment. These machines are commonly used to prepare raw materials, eliminate harmful microorganisms, enhance packaging integrity, and ensure product safety through precise quality control.

Each device is designed with compatibility in mind—seamlessly fitting into broader production workflows. Our sterilizers work with both hot-fill and cold-fill systems. Liquid nitrogen dosing machines are optimized for high-speed lines, helping prevent container deformation. Detection systems are equipped with sensors and imaging technology to catch even the smallest errors in filling, sealing, or labeling. |

|

As customer needs evolve and industry standards rise, we continue to develop and expand our auxiliary range to cover additional functions. New types of auxiliary machines will be introduced regularly, ensuring Mic Machinery remains a trusted partner for complete production solutions.

⚙ Why Auxiliary Equipment Matters

Auxiliary machines contribute significantly to operational efficiency and product reliability across multiple stages of production.

In beverage filling lines, a reliable processing unit ensures that liquids are properly blended, deaerated, and temperature-controlled before they reach the filling heads. This not only improves product consistency but also reduces waste.

In pharmaceutical and food packaging, sterilization systems eliminate harmful microorganisms, ensuring the final product is safe for consumers and compliant with health regulations.

Detection equipment plays a crucial role in quality assurance by identifying underfilled containers, cap misalignments, or foreign particles—preventing costly recalls and reinforcing brand trust.

Liquid nitrogen dosing systems enhance packaging quality by reducing oxygen exposure, which extends shelf life and stabilizes containers during high-speed filling.

These examples demonstrate that auxiliary machines are far more than accessories. They are integral parts of a high-performing production environment, working silently in the background to maintain speed, safety, and excellence.

⚙ Watch the Machines in Action

⚙ Commitment to Innovation and Service

|

At Mic Machinery, we don't just sell machines—we engineer productivity. Every auxiliary machine is backed by expert consultation, tailored configurations, and responsive after-sales support. Our design philosophy is rooted in modularity, energy efficiency, and hygiene compliance—especially for industries with strict regulatory requirements like food and pharma.

We also prioritize digital readiness. Many of our auxiliary systems are built with future-proof interfaces, enabling integration with smart factory platforms and IoT monitoring. From remote diagnostics to real-time process optimization, Mic Machinery equips your production line for both today’s demands and tomorrow’s innovations. |

Whether you're setting up a new plant or upgrading an existing line, our auxiliary solutions are designed to grow with you—adapting to future demands and helping you scale with confidence.